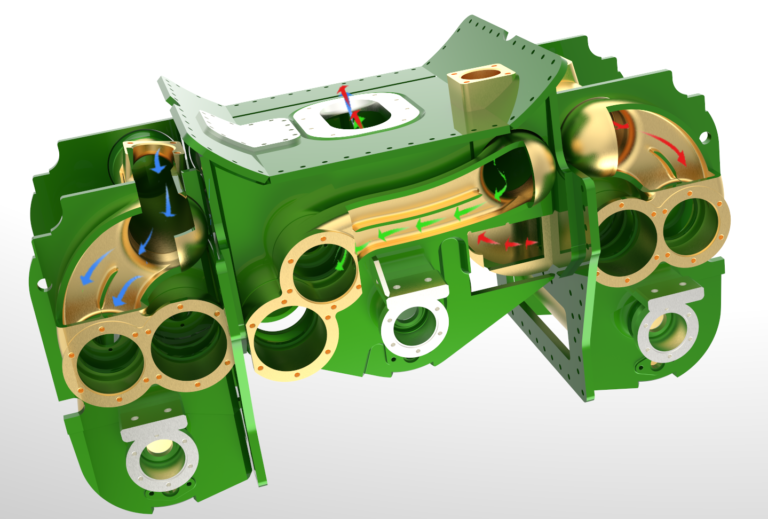

The engineering team undertook a considerable amount of work to convert the original class P2 monobloc (or one-piece) casting into a welded fabrication including Finite Element Analysis (FEA) to check for structural integrity, improving the layout of the valves to reduce the clearance volume (which affects cylinder efficiency), re-routing the steam and exhaust passages to physically separate them to prevent incoming steam from heating the outgoing exhaust, increasing the size and improve internal streamlining of steam passages along Chapelon lines to increase maximum power and improve economy and reduce the overall width of the cylinder block to provide Prince of Wales with the widest possible route availability on the main line. In addition, and as part of the continued application of modern techniques in the design and development of the improved class P2, the Trust commissioned Frewer & Co Engineers Ltd of Dorking, Surrey to undertake a Computational Fluid Dynamics (CFD) analysis of the inlet and exhaust steam passages of the cylinder block (above).

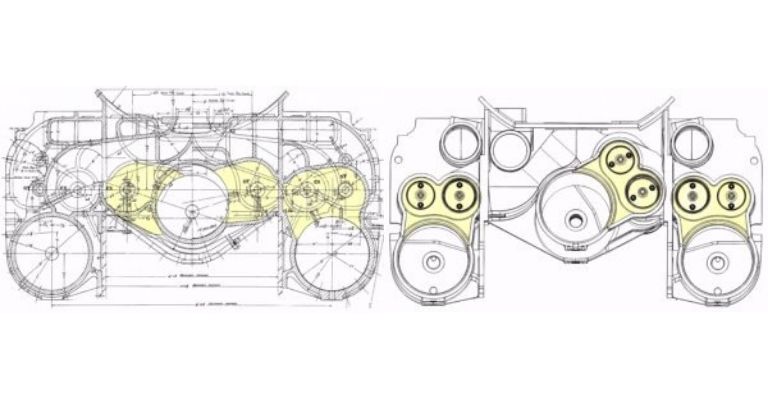

The original monobloc casting (left) and a 3D CAD of the revised arrangement for No. 2007 (right)

The Cylinder Club was launched in October 2017 to raise an initial £100,000 towards the design and construction of No. 2007’s new cylinder block – the final of four principal areas of major redesign – which it achieved within five months thanks to the generosity of our supporters. Having completed the redesign and produced the manufacturing drawings, in early 2021 the Trust approached five engineering companies with a Request for Quotation for Construction to manufacture the complex fabricated cylinder block with responses requested before the end of March 2021. Following this, the Trust commissioned Howco Group Plc to fabricate the new cylinder block, using steel castings supplied by William Cook Cast Products Ltd, with delivery of the finished monocbloc in autumn 2023.

A comparison of the steam chest areas of the two differing cylinder blocks.

The Monobloc Club seeks to raise an initial target of £250,000 from 250 supporters each donating £1,000 plus Gift Aid (in up to eight payments of £125) for the manufacture and fitment of the cylinder block.

If you would like to support No. 2007 Prince of Wales by joining The Monobloc Club then please either complete the on-line forms in section 1 or download the forms in section 2 below:

Section 1: on-line donation