Vampire

Computer modelling using VAMPIRE is a recognised technique in the UK and is usually used to optimise the design of new or modified rail vehicles and to demonstrate that they will be safe (i.e. not fall off the track!) before they are actually tested out for real. This poses a slight problem for us as all modelling assumptions in VAMPIRE are based on testing undertaken with modern vehicles (e.g. passenger vehicles fitted with air suspension); there had been no fully validated modelling of a vehicle type characterised by a rigid frame chassis, different size wheels and coupled wheelsets – until now!

The first phase of the project had therefore been to develop a fully validated model of a steam locomotive within VAMPIRE. This has to be based on an existing locomotive – and Tornado was the obvious choice! Without doing this first it simply would not be possible to undertake an accurate study on the P2. A fully validated model is one thereby the predicted and actual ride performance of the vehicle have been compared and agreed to be a sufficiently close match. Fortunately we were already aware of all this when the time came to undertake the testing of Tornado. We were asked by Network Rail to undertake some ride testing anyway, but we arranged for a few extra measuring devices (accelerometers) to be fitted as the incremental cost was minimal. Thus as she roared through the night from York to Newcastle and back as part of her own testing on that memorable evening of 18th November 2008, Tornado was also helping to pave the way for her future stablemate.

Phase one (of three) involved building a detailed computer model of Tornado within VAMPIRE, a particular challenge of which was to build a working representation of the Cartazzi rear axle, with its inclined slides. The process of validation involved simulating the York-Newcastle test run. The additional data required was the measured track data for the piece of railway she ran over (specifically the ‘up fast’ road from Tyne Yard to Tollerton). But here another wonder of the modern railway lent a hand. Network Rail’s New Measurement Train (NMT) – the yellow HST – regularly roams the length and breadth of the country’s rails, measuring the track quality. The data so recorded can be fed into VAMPIRE to allow a vehicle model to be run over any stretch of track. The memory bank was searched and the set of data nearest to 18th November 2008 over the Newcastle-York stretch found to ensure that the model simulation is as accurate as possible. By comparing the ride performance predicted by VAMPIRE with the actual ride performance measured on the night, the model was tweaked until a good match was achieved. The modelling assumptions were then be confirmed as validated.

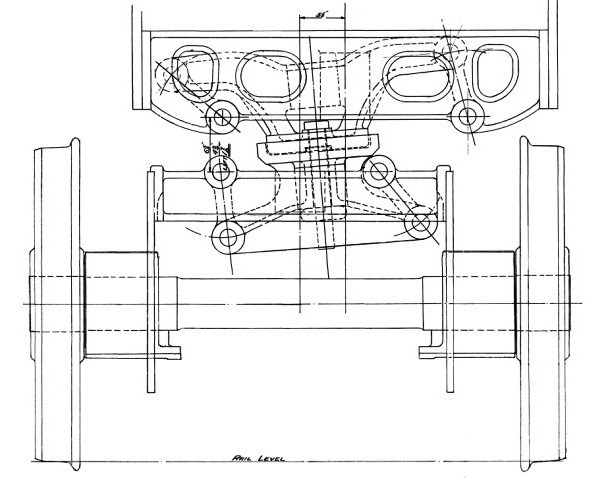

The most immediate outcome was that completion of the VAMPIRE® model of Tornado allowed us to initiate phase two of the study – construction of a VAMPIRE® model of an original P2! In order to get started on this we needed sight of some key original design drawings and the National Railway Museum was the obvious place to look. We were already aware that the drawings were part of the museum’s vast archives but, in contrast to the early days of the A1 project, this time we did not have to spend days and weeks rummaging through rolls and rolls of randomly bound drawings, being able to benefit from the tremendous advance that the ‘Search Engine’ project has delivered and it was ‘merely’ a case of reviewing the index and requesting the specific drawings we required! So, without hardly breaking a sweat, 20 key drawings for the P2 frame arrangements were secured, including front pony truck, driving wheels, axles, axleboxes, hornblocks and suspension springs. We eagerly took it to a meeting with an equally eager Owen Evans of Delta Rail for what can only be described as a good ‘drool’! One drawing even has the handwritten signature of H N Gresley himself. At least with like minds focussed round the key drawings and that idiosyncratic front pony truck arrangement, a greater appreciation was gained of the original design configuration and how the suspension worked.

The biggest challenge was to replicate the infamous swing link pony truck arrangement. Careful study of the original drawings shows how the arrangement worked, consisting of a top yoke (linked to the underframe) and bottom yoke (linked to the pony truck), with the two yokes able to rotate relative to each other (to allow for the turn of the pony truck). This has been replicated on the model by a single ‘lump’ (mass) but with a degree of flexibility. The mechanics of this arrangement have now been clearly understood, following its detail examination and modelling. Most significantly, the links were configured such that the vertical distance between the bogie and underframe increases as it ‘swings’ away from its centre line. Put another way, it is lifting the front end of the locomotive up as it negotiates the curve. This of course increases the weight on the pony truck wheelset, presumably in an attempt to help increase its steering capability. However, the unfortunate side effect of this is that it leads to the weight on the wheelset behind it (ie the leading coupled wheelset) to be correspondingly reduced (obviously, the overall weight of the locomotive has to stay the same!) The work was developed far enough to allow the movement of the suspension to be shown in animated form, which is an aid to understanding.

The original Gresley ‘swing link’ arrangement

As the virtual locomotive makes its way round a curve of increasing radius, so the lifting effect of the front pony truck starts to take effect. At first the suspension arrangement is able to compensate but it eventually gets to a stage where the inner wheel of the front coupled wheelset is lifted completely clear of the rail! It would appear therefore that the modelling work already undertaken is beginning to produce results which appear convincing and point to less-than-desirable attributes which may have been behind the reputational issues of the originals.

The remaining work of the feasibility study was undertaken, based around three objectives:

1. To check whether there was any obvious reason (in terms of vehicle dynamics) why the Trust should not

proceed with the P2 project.

2. Assuming no such reason was found, to estimate the minimum curve radius that could be negotiated by the P2 as built, and how much extra lateral clearance would be required to permit operation on sharper curves.

3. To compare the behaviour of a P2 ‘as built’ to that of a P2 with a V2-style spring control pony truck.

The results of the study were submitted to the Trust by Owen Evans of DeltaRail in report ES-2013-003 at the end of February 2013. The following is a summary of the report and its findings.

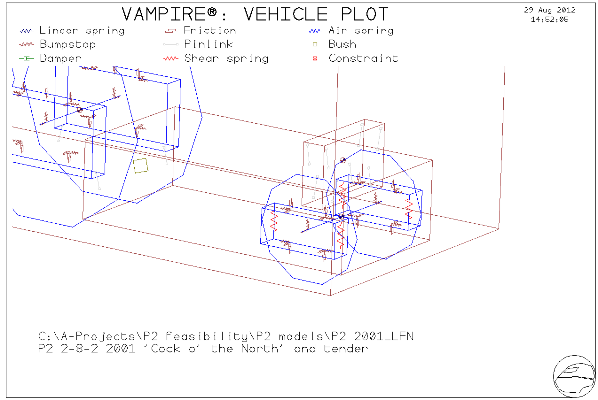

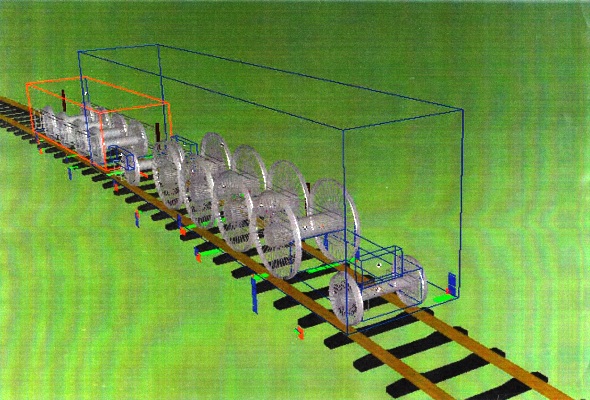

The new models of No. 2001 (‘as built’ P2) and No. 2007 (‘improved P2’ with V2-style pony truck) include some graphical information to allow much better plots to be produced than for the Tornado model. Here is the complete ‘as built’ model, showing the suspension arrangement (below).

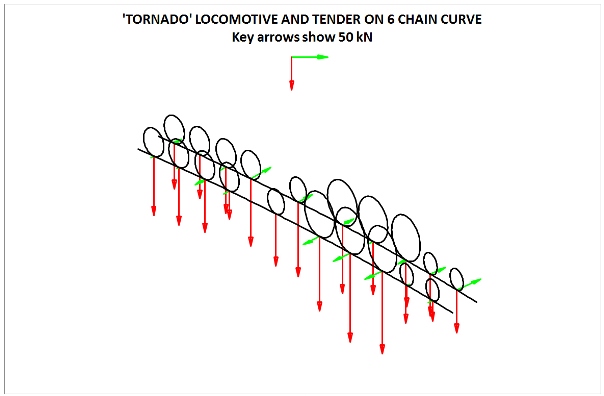

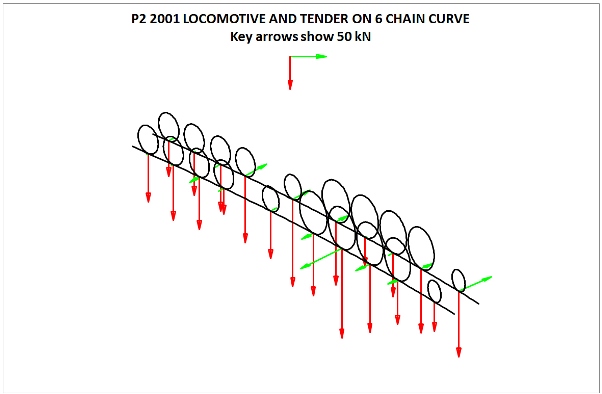

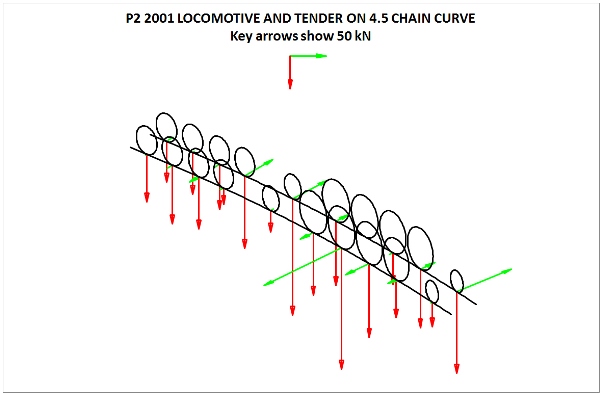

The first simulations carried out with these models was to run them round an ‘assault course’ of smooth, sharply curved sections of track. This begins with a straight, then increasing curvature to a 6 chains radius curve, followed by a further increase to 4.5 chains (with a mirror arrangement back to straight). The models were run round this track at 5 mph, and results were produced for the forces between the wheels and rails, both laterally and vertically. This simulation enables the study of the ‘track shifting’ forces; that is the total force from each wheelset that is trying to ‘straighten out’ the track. Because the coupled wheelsets are constrained to be parallel to each, they are not all aligned with the curve and have what is known as an ‘angle of attack’. In this case, not only do the wheelsets try to shift the track, they also try to spread the gauge, i.e. to force the rails apart. On gentle main line curves with good quality rail fastenings this is not too much of a problem, but in depots and sidings where curves can be much sharper there is a limit beyond which there is a real risk of derailment. There is also a link to the vertical loads on each wheel. If the lateral load (the track shifting force) builds up too much, the effect will be to push the wheel clean off the rail (ie reducing the vertical load to zero) – not a desirable result! Having explained all this, we can look at the results as Tornado, No. 2001 and No. 2007 were run round these curves.

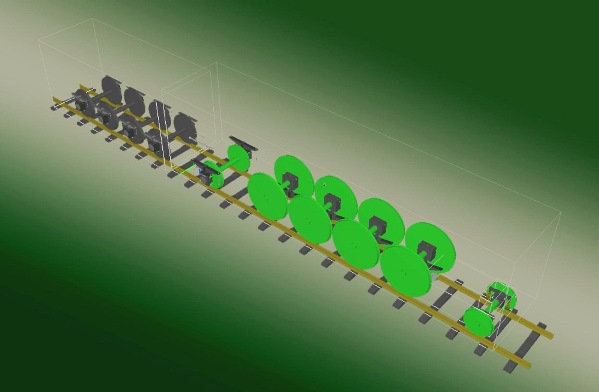

Careful study showed the greater build-up of opposing lateral (green) forces for No. 2001 and that the red (vertical) arrows on No. 2001 are quite uneven from side to side – this is most noticeable on the front pony truck. This is quite scary- the outer wheel of the third coupled wheelset has actually lifted off the rail, and the engine is doing its very best to straighten out the curve. No. 2007 actually fared little better. The work included a certain amount of adjustment of hornguide clearances to achieve the best performance for No. 2007. The conclusion was that Tornado can just manage a 4.5 chain curve whereas the minimum radius that could be achieved for No. 2007 with reasonable increases in the lateral hornguide clearances will be about 5.7 chains. It was established (from the original drawings) that No. 2001 already had thin flanges on the intermediate driving wheelsets and this feature will be retained with No. 2007.

Given that such sharp curves only appear in yards and sidings, this was deemed not to be a ‘show-stopper’, so the simulations moved on to more general behaviour out on the main line. These were based around the high speed test run with Tornado between York and Newcastle on the evening of 18th November 2008. Much useful data was gathered during that test, mainly in the form of accelerations on Tornado and her tender, as well as a full speed profile for the southbound run. Courtesy of Network Rail, the measured track geometry data for the Up Fast line between Newcastle and York (as recorded by the New Measurement Train about two weeks after the test) was recovered and fed into VAMPIRE, and the Tornado model adjusted to improve its accuracy. All three models (Tornado, No. 2001 & No. 2007) could now be put through their paces over the same track data to provide a true comparison study.

A lot of information was generated, relating to ride quality, track forces and derailment risk. In some cases the P2s were better than Tornado, for example much of the ride (especially for No. 2007) and some of the track forces (remember this route is pretty straight). In some cases No. 2001 was better than No. 2007 and in others the opposite was true. Overall No. 2007 looked better than No. 2001, but would still benefit from further refinement. One final check was ‘peak counting’. This is a somewhat complex calculation (done automatically by VAMPIRE). It looks at the lateral and vertical accelerations on the body of a rail vehicle and uses them to assess whether the vehicle is dynamically unstable. If you have ever pushed a supermarket trolley too quickly and seen the caster wheels start to vibrate rapidly from side to side, or seen a caravan snaking down the motorway, you will have witnessed dynamic instability. You can imagine that a railway vehicle behaving in this way would be quite frightening. Additionally, lack of vertical damping means that a vehicle can build up an increasing ‘bounce’ in response to features in the track to the point where it can momentarily jump clear of the rails!

Looking at our engines, the vertical behaviour is fine for all of them, even when the section between 75 and 80 mph is analysed. This is an excellent result, borne out by the actual test results from Tornado. Looking at the lateral results, some adverse behaviour is predicted, but some of this is caused by the piston thrusts causing the engine to ‘waggle’, and this is not the same thing as dynamic instability. Even so, only the fronts of the engines exceed the limits to any significant degree, and the P2s are generally better than Tornado (happily, this is an aspect where the longer rigid wheelbase is almost certainly an advantage!). Given that Tornado is now accepted as a mainline loco then this is an area where the comparison argument will be a likely way forward in terms of acceptance. Overall therefore, the verdict was that the P2 project should proceed on to the design development phase (involving more detailed dynamic analysis). Looking back, this was quite ground-breaking work, as it is almost certainly the first time that VAMPIRE has been used in this way for steam locomotives. Delta Rail completed an impressive report.

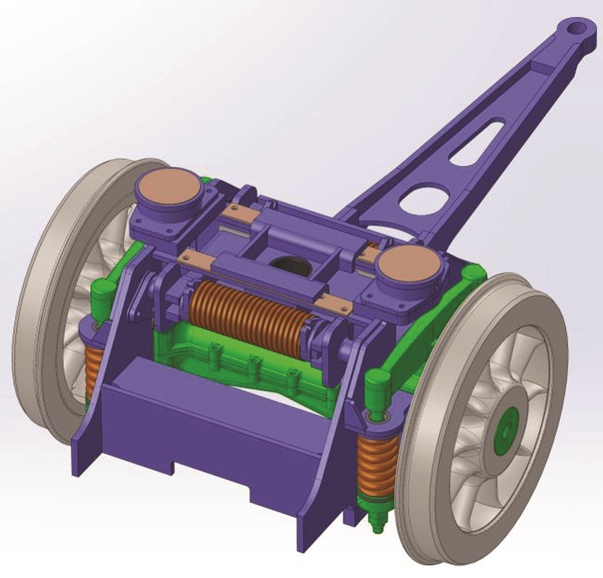

Contracts were placed with Delta Rail and Lloyds Register Rail, the former to complete the engineering studies needed to enable No. 2007 to operate on the national network and the latter the organisation that will approve the process and principles of construction. Both are critical steps. Following a meeting with Owen Evans at DeltaRail to re-start the dynamics work, wheels were drawn and added to the frame model. Crossheads, slide bars, coupling and connecting rods were also added to enable analysis of limits of increased lateral clearances on coupled wheels to permit transit of sharp curves without excessive flange scuffing.

The improved V2 pony truck as applied to No. 2007